Your ultimate guide to pipe bending in Hyderabad

Pipe Bending in Hyderabad

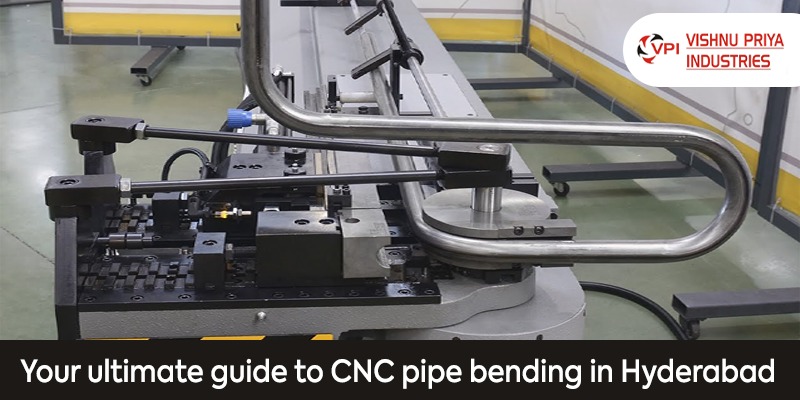

The pipe bending process has undergone significant advancements, marking a departure from traditional methods that were labor-intensive. In the past, technicians relied on manual techniques to bend pipes, a tedious process often yielding imprecise results. Manufacturing plants faced challenges as they struggled to manually bend tubes with small diameters, leading to inaccuracies in tube dimensions, cosmetic flaws, and suboptimal tube angles.

However, with the evolution of technology, the tube bending process has become more efficient, thanks to the adoption of pipe bending machines in the manufacturing industry. These modern machines have revolutionized tube bending, ensuring flawless and high-quality results. The emergence of tube bending machines has streamlined the entire process, offering precision and reliability in producing accurately bent tubes. This article explores the intricacies of Modern pipe bending in Hyderabad, shedding light on the advancements that have transformed the once cumbersome tube bending process into a seamless and precise operation.

Pipe Bending Works in Hyderabad

A pipe bender is a machine employed by modern companies for pipe bending works in Hyderabad, and its operations are entirely computer-controlled. Unlike standard tube benders that rely on heavy-duty mechanical components controlled by hydraulic systems or electrical motors, pipe benders offer advanced automation through computer programming. This results in the production of high-quality tube products that surpass the capabilities of traditional bending processes.

These machines are versatile and can handle tubes with a diameter of up to 42mm and a length of 2000mm. They are adaptable to various manufacturing needs and capable of executing single bends as well as simple and complex curves. The degree of bending can be easily adjusted to meet specific measurements, making these machines highly customizable for diverse applications.

Companies in manufacturing industries frequently utilize pipe benders for working with materials such as carbon steel, aluminum, and stainless steel. This makes them essential for creating components like fuel pumps, owing to their precision, efficiency, and ability to produce tubes with consistent quality that traditional methods may struggle to achieve.

Pipe Bending is a sophisticated manufacturing process that leverages Pipe Bending technology to shape metal sheets into desired configurations, particularly in the creation of pipes with various lengths. This method finds significant utility in industries such as automobiles, where it plays a crucial role in manufacturing exterior accessories like front guards and rear guards. The entire Pipe Bending process is orchestrated by skilled professionals, ensuring adherence to strict industry standards.

One of the notable advantages of Pipe Bending is its emergence as an alternative to welding. This process proves to be particularly effective for various gases present in the atmosphere, offering a comprehensive solution. Unlike welding, Pipe Bending eliminates the need for joints and fixtures to connect components. Instead, it skillfully molds thin metal sheets into the desired shape, providing a smooth finish. The services offered in Pipe Bending act as a viable substitute for traditional welding methods, delivering flawless products with a polished and lustrous appearance.

Achieving an accurate bend is a critical aspect of the Pipe Bending process. The entire manufacturing procedure is highly computerized, minimizing the probability of defects to near negligence. The machinery involved in bending the pipe is reliable, ensuring a perfect and clear finish that eliminates the risk of cracks or leaks. Through the utilization of exceptional Pipe Bending services, manufacturers can guarantee finished products that not only meet stringent quality standards but also exhibit an enhanced level of durability.

The success of Pipe Bending lies in the perfect collaboration of knowledge and cutting-edge equipment. To achieve excellence in molding pipes, it is imperative to combine expertise with advanced machinery, allowing for precision and accuracy in the manufacturing process. The assembly of tubular structures must be executed with meticulous attention to detail, conforming to established industrial norms.

Furthermore, the manufacturing of pipes takes into account specific industrial requirements and norms. Different industries may have varying specifications; for instance, some industries demand pipes with minimal oil content, while others, like the aerospace industry, require a significant amount of oil due to a higher susceptibility to leaks and cracks. In response to these diverse needs, Pipe Bending services ensure the production of pipes that align with all relevant industrial norms and specifications. This versatility and attention to industry-specific details make Pipe Bending a valuable and adaptable solution for a wide range of applications.

Pipe Bending stands as a sophisticated and reliable manufacturing process that not only meets but exceeds industry standards. Its computerized precision, elimination of welding requirements, and adherence to specific industrial norms make it a preferred choice for industries seeking high-quality, durable, and precisely crafted pipe components. As technology continues to advance, Pipe Bending is likely to play an increasingly pivotal role in shaping the future of metal fabrication processes.

Pipe Bending at Vishnu Priya Industries:

At Vishnu Priya Industries, we take pride in offering high-quality Pipe Bending Job Works in Hyderabad, providing precise shaping of various metals. Our commitment to perfection, precision, and timeliness sets us apart, and we utilize state-of-the-art Pipe Bending-operated machines, including 5 axis pipe bending, to meet the diverse needs of our clients.

Services Overview:

1. State-of-the-Art Pipe Bending Machines:

Our Pipe Bending services leverage advanced Pipe Bending-operated machines, ensuring accuracy and efficiency in metal shaping. The utilization of cutting-edge technology, such as 5 axis pipe bending, allows us to achieve complex bends with precision.

2. Timely and Efficient Job Works:

We understand the importance of timely project completion. Our Pipe Bending Job Works are conducted with efficiency, ensuring that your projects are completed on schedule. This commitment to timely delivery sets the foundation for our client-centric approach.

3. Budget-Friendly Rates:

Quality metal shaping should be accessible to all our clients. Therefore, we offer our Pipe Bending services at budget-friendly rates without compromising on the precision and quality of our work. This ensures that our clients receive exceptional value for their investment.

4. Experienced and Efficient Team:

Our Pipe Bending Job Works are executed by a highly efficient and experienced team. Committed to delivering the best possible results, our team is well-versed in operating machines and possesses the expertise needed to meet the diverse requirements of our clients.

5. Diverse Metal Shaping Solutions:

Whether you require standard pipe bends or intricate shapes, our Pipe Bending services cater to a wide range of metal shaping needs. The versatility of our machines allows us to handle various materials, including steel, aluminum, and copper.

Our expertise extends beyond Pipe Bending to encompass comprehensive laser-cutting solutions. Feel free to get in touch with us, and let our skilled team assist you in achieving precision and excellence in metal fabrication.

Vishnu Priya Industries stands as a reliable provider of Pipe Bending Job Works in Hyderabad, offering a combination of cutting-edge technology, efficiency, and affordability. Our dedication to delivering high-quality results makes us the preferred choice for clients seeking precision in metal shaping and laser cutting services.

Precision in Pipe Fabrication

The pipe bending process involves loading a straight pipe into the machine, where clamps secure its position. Programming the machine with the desired bend angle and radius initiates the bending process. Hydraulic pressure and a mandrel, a cylindrical tool, are employed to bend the pipe accurately while maintaining its shape. This computerized process ensures a high level of accuracy, making it a preferred method for bending pipes made of steel, aluminum, copper, and other materials.

Applications Across Industries

Pipe bending has widespread applications in diverse industries, including construction, automobile manufacturing, aerospace manufacturing, and general manufacturing. In construction, it is employed to create bespoke pipe fittings for plumbing and HVAC systems. The automotive industry benefits from Pipe bending in the production of exhaust systems and various components. The aerospace sector, known for its precision requirements, relies on Pipe bending for critical applications.

Expertise in Pipe Bending

In Hyderabad, Pipe Bending Works are carried out by highly qualified specialists who are proficient in operating machines. This expertise ensures the manufacturing of precise bends in pipes of varying sizes and materials, meeting stringent quality standards. The seamless collaboration of skilled professionals and advanced technology results in high-quality and durable products.

sheet metal bending involves the use of specialized equipment to bend thin plates with precision. press brakes are integral to this process, allowing for the manipulation of sheet metal pieces ranging from a few millimeters to several meters in length. In Hyderabad, Sheet Metal Bending plays a crucial role in various industries, offering flexibility and adaptability in sheet metal fabrication.

The sheet metal bending machine consists of essential components, including the bracket, worktable, and clamping plate. The worktable, comprising a base and pressing plate, is pivotal in controlling the bending process. Hinged connections facilitate the attachment of the base to the clamping plate, providing precise control over the bending of sheet metal.

Applications and Versatility

Sheet Metal Bending in Hyderabad caters to a wide range of applications, from bending small pieces for intricate components to handling larger sheets for diverse industrial needs. The versatility of technology allows for the efficient bending of sheet metal to meet specific design requirements, contributing to the adaptability of the process.

Machining Excellence

Pipe Bending Job Works in Hyderabad encompasses a diverse range of machining services conducted using Pipe Bending equipment. These services address various manufacturing needs, offering precision machining for components and the fabrication of intricate parts for different industries. Pipe Bending Job Works play a pivotal role in meeting the demands of modern manufacturing with enhanced accuracy and efficiency.

Utilization of Pipe Bending Machines

Pipe Bending Job Works involve the utilization of Pipe Bending machines for milling, turning, drilling, and other machining operations. The flexibility of Pipe Bending technology enables the production of complex and intricate components with tight tolerances, surpassing the capabilities of traditional manual machining methods.

Applications and Future Trends

Pipe Bending Job Works cater to industries such as automotive, aerospace, electronics, and more. The advanced capabilities of Pipe Bending machines position these services at the forefront of modern machining, driving innovation and excellence in manufacturing. As technology continues to advance, the role of Pipe Bending Job Works in Hyderabad’s industrial landscape is poised to grow, contributing to the evolution of machining processes.

In conclusion, Pipe Bending Pipe Bending Works, Pipe Bending Sheet Metal Bending, and Pipe Bending Job Works collectively represent the forefront of modern manufacturing processes in Hyderabad. These technologies, driven by Pipe Bending advancements, ensure precision, efficiency, and adaptability in meeting the diverse requirements of industries. As technology continues to advance, the role of Pipe Bending machining in Hyderabad’s industrial landscape is poised to grow, driving innovation and excellence in manufacturing.

FAQ

1. What is Pipe Bending?

Pipe Bending refers to the process of bending pipes using Pipe Bending machines. These machines are programmed to accurately bend pipes to specific angles or forms, offering precision and efficiency in the manufacturing process.

2. How does Pipe Bending differ from traditional methods?

Unlike traditional methods that rely on manual techniques, Pipe Bending utilizes automated machines. This automation ensures higher accuracy, faster production, and the ability to achieve complex bends with consistency.

3. What materials can be used in Pipe Bending?

Pipe Bending is versatile and can be applied to various materials, including steel, aluminum, copper, and other alloys. This flexibility makes it suitable for a wide range of industrial applications.

4. What industries commonly use Pipe Bending?

Pipe Bending is widely used in industries such as construction, automotive manufacturing, aerospace, and general manufacturing. It is employed for creating customized pipe fittings, exhaust systems, and other components.

5. How does the Pipe Bending process work?

The process begins by loading a straight pipe into the machine, and securing it with clamps. The machine is then programmed with the desired bend angle and radius. Hydraulic pressure and a mandrel are used to bend the pipe accurately as it passes through the machine.

6. What are the advantages of Pipe Bending?

Pipe Bending offers advantages such as high precision, repeatability, and the ability to produce complex bends. It eliminates the need for manual labor, resulting in faster production and reduced chances of errors.

7. Can Pipe Bending be used for large-scale production?

Yes, Pipe Bending is well-suited for large-scale production. The automated nature of machines allows for the rapid and efficient bending of pipes, making it an ideal choice for mass production.

8. What types of bends can be achieved with Pipe Bending?

Pipe Bending can achieve a wide range of bends, including tight and intricate bends to sweeping curves. The versatility of machines allows for the production of bends with varying angles and radii.

9. Is Pipe Bending suitable for different pipe diameters?

Yes, Pipe Bending machines come in various sizes to accommodate different pipe diameters. They can handle pipes with diameters ranging from small to large, providing flexibility for diverse applications.

10. What role does precision play in Pipe Bending?

Precision is a key aspect of Pipe Bending. The computerized control ensures accurate and consistent bends, minimizing the likelihood of defects. This precision is crucial for industries that require high-quality and standardized pipe components.